- Home

-

About Us

-

Products

-

System Solutions

-

Backbone Network System Solutions

-

FTTx Solution for Multi-storey Dwelling Block

-

FTTx Solution for High-storey Dwelling Block

-

FTTx Solution for Villa Dwelling Block

-

FTTA Fiber and Power Hybrid Cable(FPHC)Solutions Base Station in 4G/5G Wireless System

-

Railway & Rolling Stock Solution

-

Power Transmission and Distribution Solution

-

Power Transmission Line System Solutions

-

Marine and Offshore Solution

-

Wind Power Solution

-

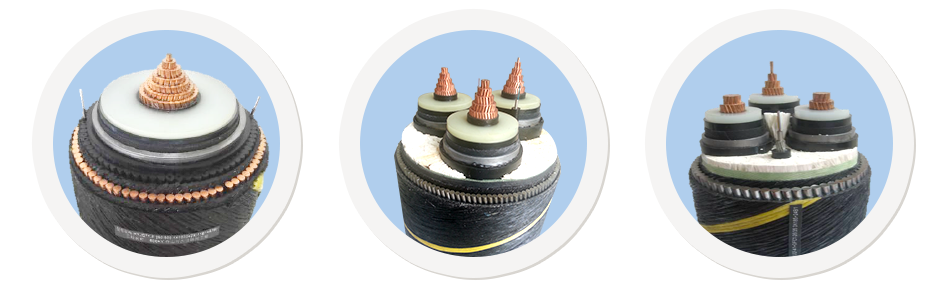

Submarine Cable Solution

System Solutions

More -

-

News

- ESG

-

Company Culture

- Contact Us